| Sign In | Join Free | My chinaqualitycrafts.com |

|

- Home

- Products

- About Us

- Quality Control

- Contact Us

- Get Quotations

| Sign In | Join Free | My chinaqualitycrafts.com |

|

Brand Name : HENGYUAN

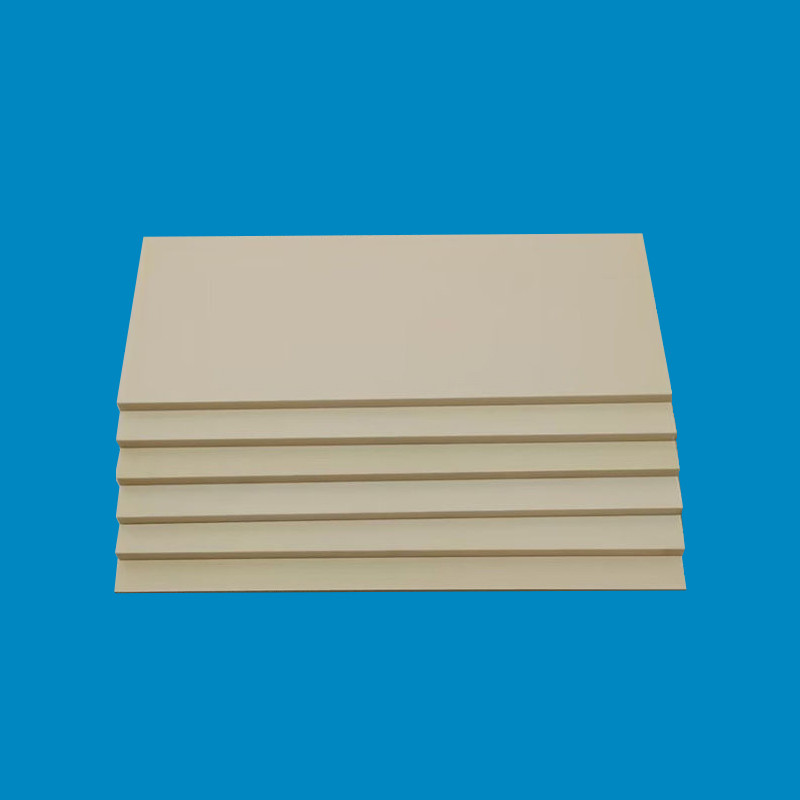

Model Number : 99% Alumina Ceramics

Certification : CE,UL

Place of Origin : WUXI JIANGSU CHINA

MOQ : 100

Price : Negotiable

Supply Ability : 5000 PCS/WEEK

Delivery Time : 20 DAYS

Packaging Details : Carton

Material : 99% Alumina Ceramics

Density : 3.85g/cm³

color : White or yellow

Shape : Customizable

OEM,ODM : Acceptable

Orgin : WUXI JIANGSU CHINA

MOQ : 100 PCS

Package : Carton

Alumina ceramics are precision ceramic materials widely used in various industries. Al2O3 ceramic cutting tools are widely used for cutting difficult to machine materials such as hard cutting, high-speed dry cutting, and high-speed cutting due to their high hardness, strong high-temperature mechanical properties, good wear resistance, good chemical stability, and resistance to bonding with metals. The cutting speed of alumina ceramic cutting tools is higher than that of general hard alloy cutting tools, which can greatly improve the cutting efficiency of different materials.

| Naterial | Unit | A95% Alumina Ceramics | A97% Alumina Ceramics | A99% Alumina Ceramics | A99.7% Alumina Ceramics |

| Density | g/cm³ | 3.6 | 3.72 | 3.85 | 3.85 |

| Flexural Strength | Mpa | 290 | 300 | 350 | 350 |

| Compressive Strength | Mpa | 3300 | 3400 | 3600 | 3600 |

| Modulus of Elasticity | Gpa | 340 | 350 | 380 | 380 |

| Impact Resistance | MPam1/2 | 3.9 | 4 | 5 | 5 |

| Weibull Modulus | M | 10 | 10 | 11 | 11 |

| Vickers Hardulus | HV0.5 | 1800 | 1850 | 1900 | 1900 |

| Thermal Expansion Coefficient | 10-6K-1 | 5.0-8.3 | 5.0-8.3 | 5.4-8.3 | 5.4-8.3 |

| Thermal Conductivity | W/Mk | 23 | 24 | 27 | 27 |

| Thermal Shock Resistance | △T℃ | 250 | 250 | 270 | 270 |

| *Maximum Use Temperature | ℃ | 1600 | 1600 | 1650 | 1650 |

| Volume Resistivity at 20℃ | Ω | ≥1014 | ≥1014 | ≥1014 | ≥1014 |

| Dielectric Strength | KV/mm | 20 | 20 | 25 | 25 |

| Dielectric constant | εr | 10 | 10 | 10 | 10 |

|

|

Maximize Efficiency With 99% Alumina Ceramics Part For High Temperature Environments Images |